Welding, an essential process in various Australian industries such as manufacturing, mining, and construction, is fraught with hazards. Even with the use of comprehensive safety equipment, workers may be exposed to harmful fumes, blinding light, and burns.

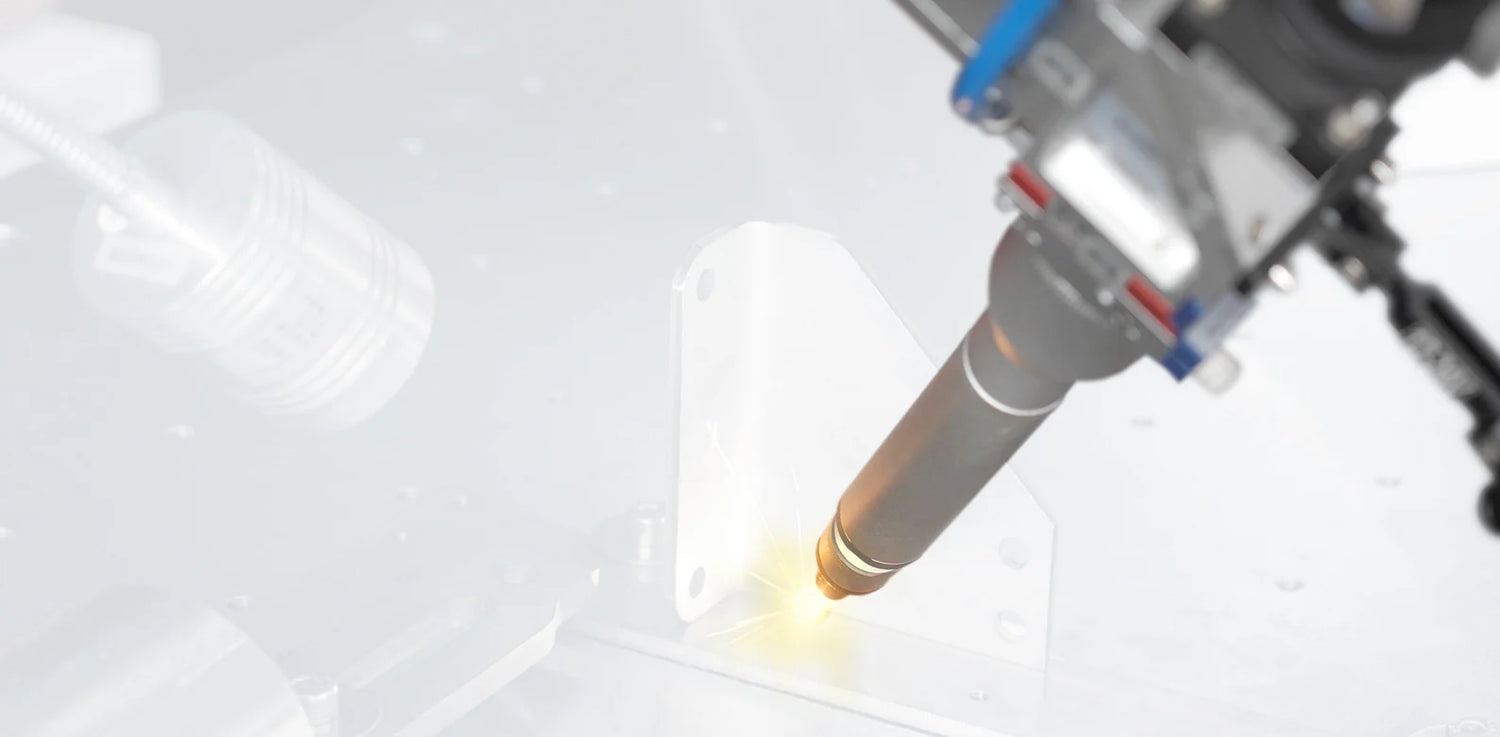

Our collaborative welding robot MexxBot mitigates these risks while simultaneously improving the operational efficiency of businesses.

A Safer Welding Environment with MexxBot

MexxBot represents a significant leap forward in welding technology, incorporating collaborative robotics that minimise the hazards associated with traditional welding processes. This state-of-the-art robot is engineered to work alongside human operators to drastically reduce human exposure to the myriad of risks outlined by Safe Work Australia and Worksafe Queensland.

Minimising Exposure to Harmful Fumes

Equipped with advanced ventilation systems, MexxBot can operate in enclosed environments, reducing workers' exposure to toxic fumes and gases such as Hexavalent Chromium compounds - a carcinogenic byproduct of welding stainless steel.

Reducing the Risk of Burns and Radiation

By allowing operators to supervise welds from a safe distance, the risk of burns from hot materials and exposure to harmful radiation is significantly reduced.

Enhancing Precision and Reducing Errors

Automated systems provide consistent, high-quality welds, decreasing the likelihood of accidents caused by welding errors.

Versatility in Application

The versatility of MexxBot means that it can be deployed in various settings, including manufacturing warehouses, mining gas pipelines, oil rigs, coal mining quarries, and servicing depots.

Beyond Safety: The Efficiency of MexxBot

In addition to providing a safer welding environment, MexxBot offers unparalleled efficiency. Its precision and consistency ensure high-quality welds, reducing rework and waste materials. The ability to operate 24/7 without fatigue ensures that projects can be completed more quickly and cost-effectively.

Collaborative Welding in Australia

The introduction of MexxBot by Mexx Engineering marks a pivotal moment in the evolution of welding practices in Australia. By exceeding Australia's safe work requirements, MexxBot not only ensures the health and safety of workers but also heralds a new era of efficiency and productivity in the welding industry.

As industries continue to adopt MexxBot and similar technologies, we can anticipate a significant reduction in workplace injuries and illnesses related to welding, propelling Australia to the forefront of safe and efficient industrial practices. MexxBot exemplifies how technological innovation can transform traditional processes, ensuring worker safety while enhancing productivity and quality—a win-win scenario for both workers and industries alike.